Bagging Powders & Bulk Solids

Bag Packaging and Palletizing Equipment

THIELE - SYMACH

Packaging powders and bulk solids from food to chemicals and building materials

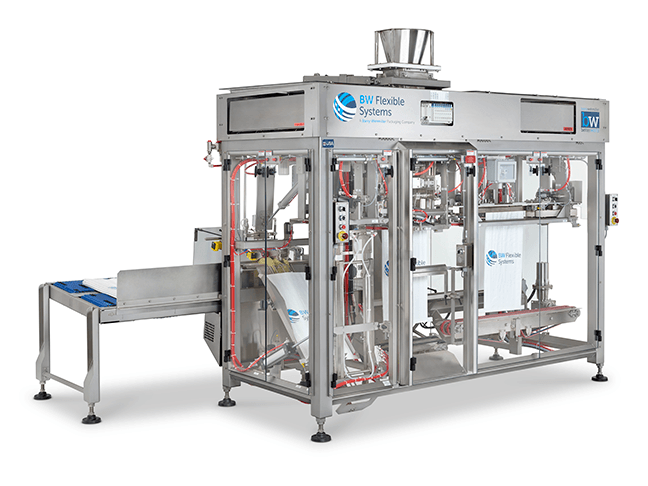

BW Flexible Systems' THIELE bag filling and SYMACH palletizing equipment offers the packaging flexibility you require to bring your powdery or granular products to market.

Three powerful advantages

1. They're operator friendly

Thiele

Thiele baggers employ an intuitive HMI that has been designed to facilitate quicker, repeatable changeovers. Developed from years of customer feedback and engagements, Thiele's HMI includes features like fault display messaging for stop recovery and active downtime monitor logging which provides easy access and insight into downtime tracking data.

Thiele machines also employ refined ergonomically designed magazine and access doors as well as cycle counters for batch runs.

Symach

With a Symach Palletizer, it has never been easier to repeatedly deliver precisely-constructed, well-stacked pallets. Our palletizers have been refined with your ease-of-use in mind, that's why we include features like drag and drop patern set-up, so that your operators can quickly and efficiently design and implement product placement on the pallet.

In addition, Symach Palletizers come equipped with Allen Bradley controls, wrapping systems, and manage data for machine counting.

2. They deliver improved operation

Thiele

At BW Flexible Systems, we're always working to help you produce consistent, high-quality bags. With a Thiele bag filling solution, you'll enjoy internal sealing for most bag types, so sealed bags exit the machine. Integrated scale control is also nested into the bag filling HMI - giving you quick, easy access to the scale and weighment controls.

Our Thiele OmniStar includes many features that make it a stand-out powder and bulk solids packaging platform. Learn more about the OmniStar's advantage in powder and bulk solids.

Thiele machines can also be equipped with available printing solutions. Be sure to ask for more information!

Symach

When it comes to palletizing, no one wants to spend time wrestling with poorly constructed pallets. That's why Symach offers advanced palletizing features that stack up to expertly constructed pallets; features like bag overlap settings for large bags, precision bag placement, and a stacking cage that ensures no product lean on the pallet.

3. Accurate Weighments

Precise and accurate weighments make a big difference, that's why Thiele has spent so much time and effort developing parts and systems that provide you with industry-leading weighment precision and accuracy. This research and development pays off in equipment like our Auger-Fed Net Weigh Scale, the 9908.

The Model 9908 Simplex Auger-Fed Net Weigh scale features a dual stage bulk and trim auger delivery system that employs variable speed drives to optimize speed and accuracy. The 9908 also comes equipped with a food-grade belt to feed the bulk and trim delivery. Download the Model 9908 Simplex scale brochure to learn more.

By implementing high-quality, rigorously tested scales and developing HMI features, such as integrated scale control and monitoring systems, you can be confident that a Thiele bag filler will deliver consistently excellent bags time and again.

Ready to learn more? Contact us today to learn more and discover the BW Flexible Systems difference.

Request More Information

The New Bulk Solids & Power Packaging All-Star

Thiele OmniStar

Our OmniStar bag filler comes equipped with features that make it a stand-out bulk and powder packaging performer. Dealing with dusty particulates? The OmniStar's Lexan covers prevent dust ingress without sealing or covering the area around spouts and vacuum lines. A flexible skirt seal is also available between the scale discharge hopper and bagger movable hopper.

In addition to its outstanding dust control, the OmniStar maintains constant control of both empty and filled bags during filling and transferring to the sealing systems, insuring consistent, uniform sealed bags.

OmniStar features include:

- Discharge spouts that do not allow product spillage upon air loss.

- Shakers/settlers in the fill stations

- Class II, Division 2, Group F & G area classification, includes:

- Dust-tight enclosures & wire-way.

- Intrinsically safe solenoid valves, sensors, cables and I/O Modules.

- Static dissipative belting where applicable.

- . . . and more!

The Thiele Advantage

3 more Thiele innovations

At BW Flexible Systems, we are always working to improve upon and refine our equipment and service. That's why our machines have a reputation for rugged reliability and innovative features and operation.

When it comes to bulk product packaging and large bag operations, our Thiele brand is among the most relied-upon brands in the field, packaging many thousands of pounds of product around the world each day. Discover why Thiele has earned a reputation for ease of use, reliability, and innovation.

Bag Air Deflation System

Thiele introduces a breakthrough in bag filling quality with the innovative bag deflation system. Because bag palletizing is critical to overall packaging quality, Thiele's engineers developed the bag deflation system to reliably remove air from the bag top prior to sealing.

Adjustable Spout

Thiele's Adjustable Spout feature allows for fast, accurate changeovers. The spout open position is adjustable via a servo motor from the HMI—a vast improvement from traditional mechanical adjustments. The more bag sizes are changed, the more our adjustable spout makes sense.

Bag Top Registration

Thiele's Bag Top Registration system, a feature of our Thiele Star bag filling system, maximizes bag quality and quantity by adjusting each bag’s position prior to placement in the transfer mechanism, ensuring each bag is sealed in the correct place, time after time.

© 2021 BW Flexible Systems